How To Buy

How To Use

How To Finish Turn

How To Buy

How To Use

How To Finish Turn

|

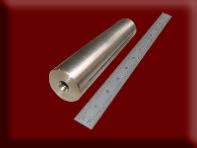

Standard Available Diameters |

||

|

Range Letter |

Max Body |

Min Body |

|

0.313 |

0.250 |

|

|

0.500 |

0.313 |

|

|

0.750 |

0.375 |

|

|

1.000 |

0.75 |

|

How do I read Xpandrel part numbers

What materials can be used

|

10AAS2WL4SBSHTS- |

|

10AAE2WL6SBSHTS- |

|

10AAS4WL6SBSHTS- |

|

10AAE4WL8SBSHTS- |

|

10AS2WL4SBSHTS- |

|

10AE2WL6SBSHTS- |

|

10AS4WL6SBSHTS- |

|

10AE4WL8SBSHTS- |

|

10BS2WL4SBSHTS- |

|

10BE2WL6SBSHTS- |

|

10BS4WL6SBSHTS- |

|

10BE4WL8SBSHTS- |

|

10BS6WL8SBSHTS- |

|

10BE6WL10SBSHTS- |

|

10CS4WL6SBSAAS- |

|

10CE4WL8SBSAAS- |

|

10CS6WL8SBSAAS- |

|

10CE6WL10SBSAAS- |

|

10CS8WL10SBSAAS- |

|

10CE8WL12SBSAAS- |

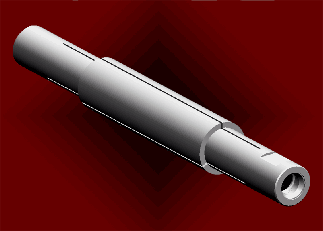

Typical 1000 series with both end conditions standard and single actuation on both ends

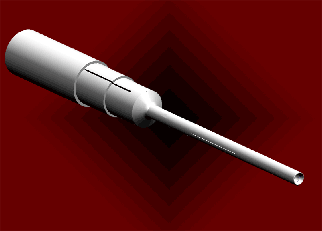

1000 series with both end conditions standard and single actuation on both ends. Added turned down ends and wrench flats.

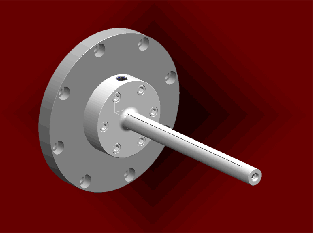

1000 series with a mounting plate added to a flanged end and one end standard . Single side actuation on the flanged end and single end actuation on the standard end.

1000 series with asymmetrical end conditions (one end oversized and extended,one end standard) Single actuation on both ends. Added stepped features.

Versitility....that is the Xpandrel Advantage.

1000 series can be configured with most of the available end conditions and actuation methods.

This series is standardly available with either both ends standard, or with one extended chucking end.